With such successful businesses using Lean Six Sigma tactics, executive leadership at Allied Machine understood the importance of educating key players to shape the continuous improvement culture and sustain process excellence. The methods worked so well, that by 2009, 82% of Fortune 100 businesses had implemented Lean Six Sigma practices into their business strategies.

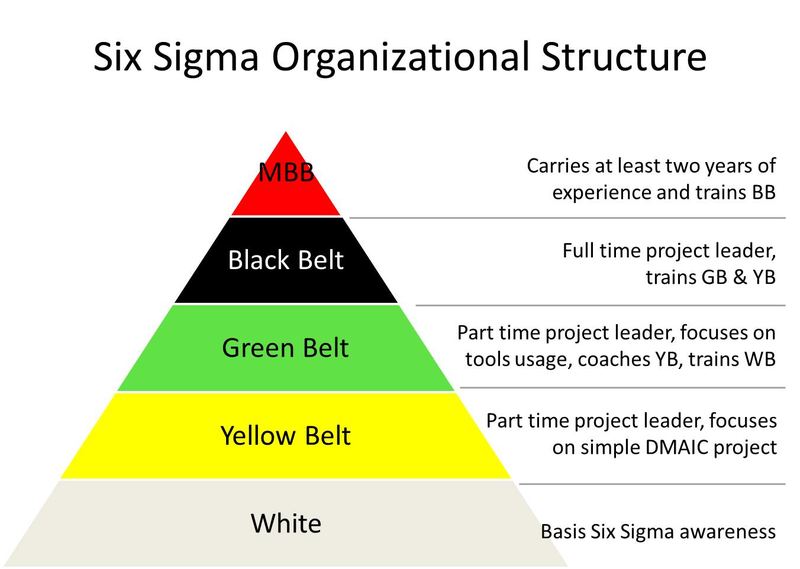

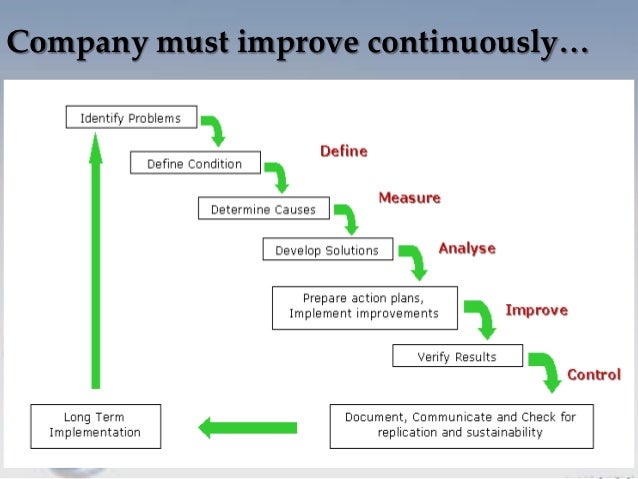

As defects are reduced, waste is reduced, so the two practices complement each other well. In the 2000’s, companies began combining the quality improvement systems of Six Sigma with the waste reduction methods of Lean Manufacturing, creating the term Lean Six Sigma. Initially Lean Six Sigma was used exclusively in parts manufacturing, but over time companies like 3M and GE started using it in other areas too. The name originates from a statistical measure, and the goal is to consistently produce no more than 3.4 defects per million opportunities (DPMO). Motorola’s Bill Smith coined the term in the early 1980’s. Lean Six Sigma methods are rooted in process improvement systems like Total Quality Management (TQM) and evolved over time. Investing in Lean Six Sigma’s black belt training is intimidating, but businesses committed to educating employees in key roles throughout their organization see long-term benefits in customer satisfaction, work culture, and their efficiency. Not to mention, it’s particularly rigorous and certification is not guaranteed. Allied Machine invests in large-scale Lean Six Sigma education for continuous improvement.ĭover, Ohio: Why do companies like 3M, GE, Ford, and even a 78-year old, family-owned cutting tool manufacturer like Allied Machine & Engineering continue to invest in black belt training? After all, it’s time consuming, expensive, and pulls valuable employees from their daily commitments.

0 kommentar(er)

0 kommentar(er)